insulate naturally

Discover forest climate at home

request a free brochure

insulate naturally

Discover forest climate at home

request a free brochure

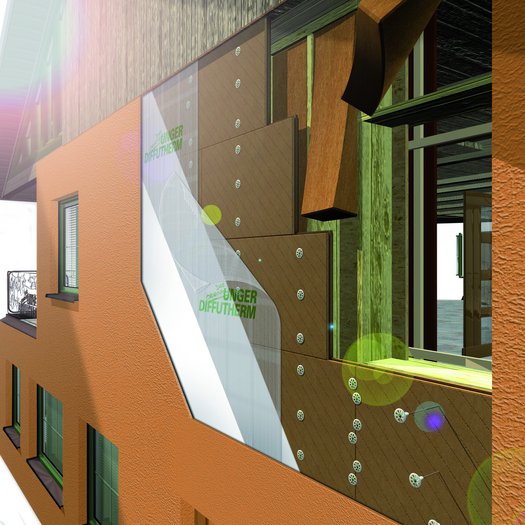

UdiSPEED® SYSTEM Exterior Insulation System for Timber Constructions

UdiSPEED® SYSTEM Exterior Insulation System for Timber Constructions

- Warp-free in long-term behaviour

- For houses made of wood, such as wooden frame, wooden stand or wooden panel

- Permeable construction

- Surface grooves ensure permanent wood moisture balance at 4 cm

- Minimal waste as it can be used on both sides

- Good sound insulation due to high density

UdiSPEED® SYSTEM – The efficient wood-fibre insulation system for timber-frame buildings.

UdiSPEED® is a robust, universal render-bearer board made from natural, stainable wood fibres. The insulation boards are available in 40 and 60 mm thicknesses. It has been designed for use as a special, vapour-permeable cladding for façades. In combination with our Udi Fine Plasters, the insulation system meets all the requirements for environmentally-friendly timber constructions without vapour barriers as well as for the renovation of pre-fabricated houses with external particle boards.

The unique grooved surface structure ensures permanently warp-free surface. This product embodies more than 20 years of experience in the area of timber construction.

Installation Constructions

The UdiSPEED® SYSTEM was designed as a complete system and coordinated in terms of its functionality and durability. To ensure a permanent insulating effect, long-term weather protection and optimal wall fixing, the individual accessories were developed to produce a complete system solution. This combination has proven itself through its consistent, high product quality. Further decisive factors are the practical installation details. Working together with professionally trained and licensed specialists and tradesmen we have developed solutions and the related accessories for all areas from the cellar to the roof. Don’t take any risks with your façade insulation.

Step 1. Mounting and fixing

Beginning from the bottom to the top, the wood-fibre boards are mounted to the level surface of the substrate so that the joints are offset. They are then secured using our UdiASSEMBLY SDH RECO® system fixings to provide a permanent and storm-proof fixture. This provides the wall with a completely wind-proof cladding. The lower edge is formed with a plinth reveal and sealed using our UdiBASE® Plinth Profile System. An appropriate water-resistant insulation is employed in the rainwater splash zone of the plinth.

Step 2. Base coat and reinforcing mesh

The subsequent coating of the wood-fibre insulation boards provides the system with increased external stability, permanent crack coverage and weather protection. The specially developed reinforcing coating UdiFOUNDATION® COAT is applied using a toothed trowel to a minimum depth of 5 mm and the UdiREINFORCEMENT® Strengthening Mesh is then bedded-in to the coating. This is the base for a durable and crack-free top layer of finishing plaster.

Step 3. Priming the plaster top coat

Depending on the type of finishing plaster system that has been chosen, the appropriate render primer is applied, by rolling or spraying, across the whole surface of the UdiFOUNDATION® COAT to ensure that the finishing coat adheres properly to the base coat.

Step 4. Applying the finishing plaster

The scratch-finish, rubbed-finish or smooth-finish plaster is then applied to the dry surface and is then structured according to the chosen granularity and design preference. This provides a permanent, weather-resistant surface. We offer a wide range of high-quality fine plasters:

- UdiPERL® – STRUCTURED FINE QUALITY PLASTER with 15 year guarantee package.

- UdiSILANO® – SILICON FINE QUALITY PLASTER SYSTEM

- UdiORGATO® – ORGANIC FINE QUALITY PLASTER SYSTEM

- UdiSIKATO® – SILICATE FINE QUALITY PLASTER SYSTEM and PAINTS

- UdiMIRALO® – MINERAL FINE QUALITY PLASTER SYSTEM and PAINTS

Additional paint coatings are recommended but, with the exception of the UdiMIRALO® System, not absolutely necessary.